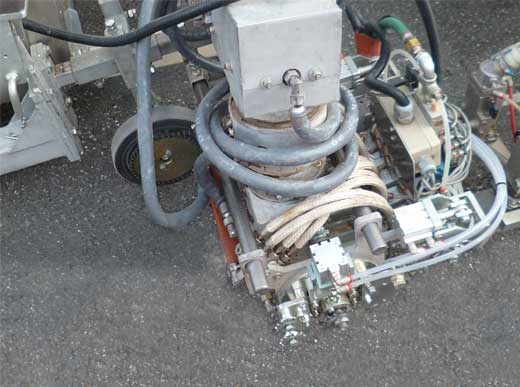

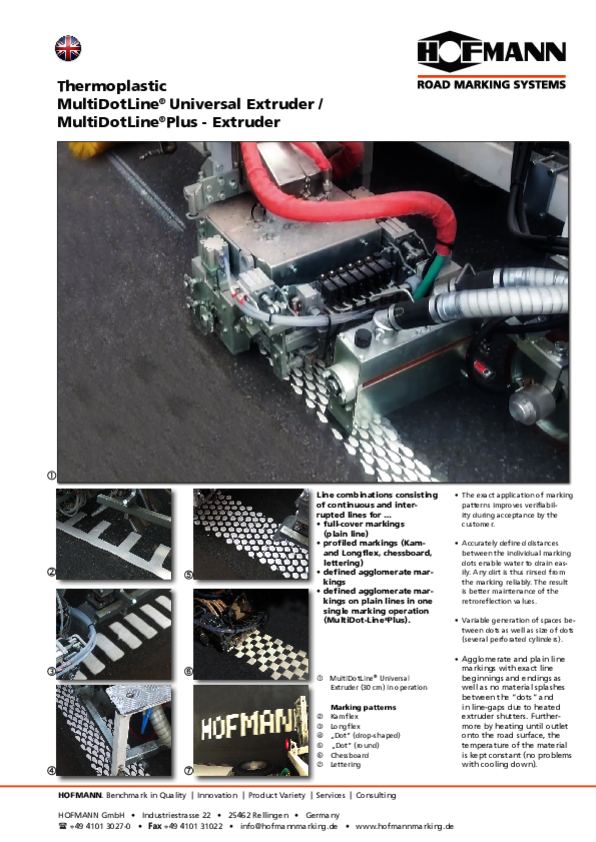

Thermoplastic MultiDotLine® Universal Extruder / MultiDotLine®Plus Extruder – our hot dot and line solution

Line combinations consisting of continuous and interrupted lines for:

- full-cover markings (plain line)

- profiled markings (Kam- and Longflex, chessboard, lettering)

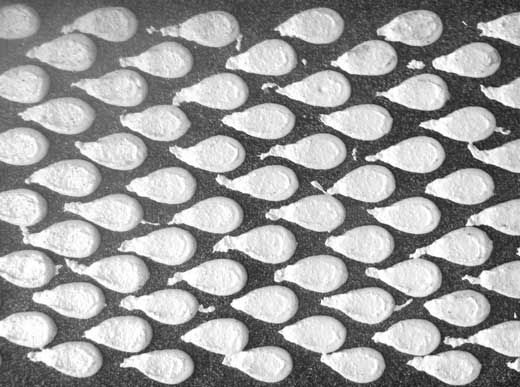

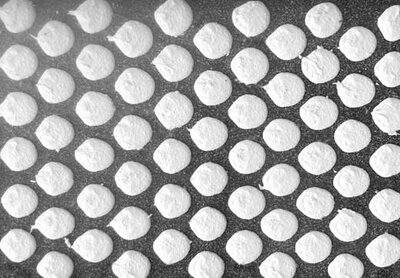

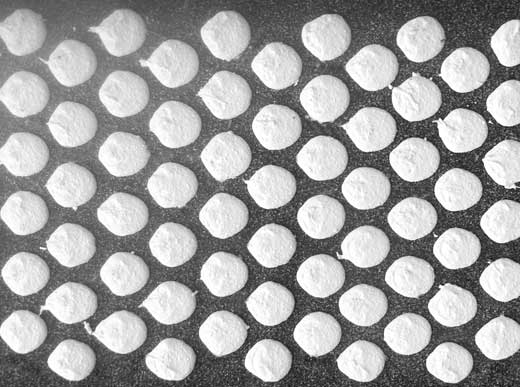

- defined agglomerate markings

- defined agglomerate markings on plain lines in one single marking operation (MultiDot-Line®Plus)

Features

Available application techniques

Thermoplastics

Thermoplastics

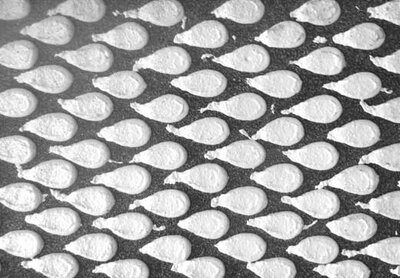

The exact application of marking patterns improves verifiability during acceptance by the customer.

Accurately defined distances between the individual marking dots enable water to drain easily. Any dirt is thus rinsed from the marking reliably. The result is better maintenance of the retroreflection values.

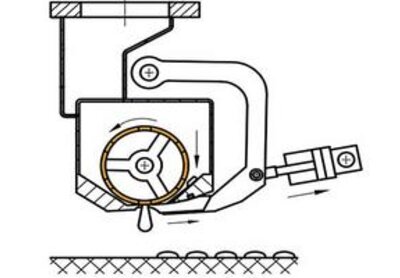

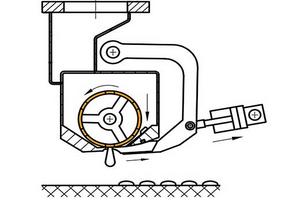

Variable generation of spaces between dots as well as size of dots (several perforated cylinders)

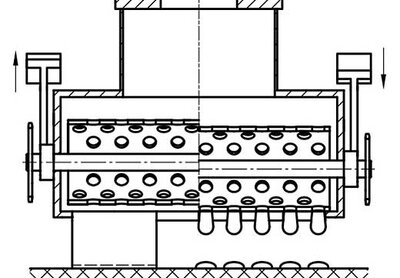

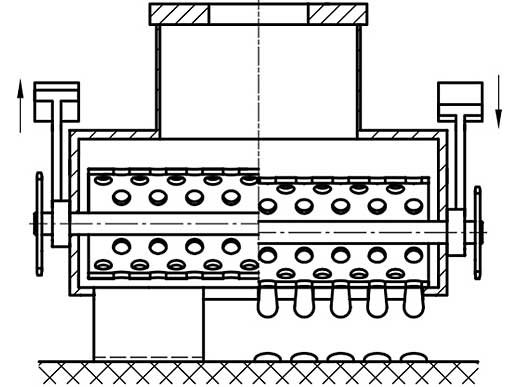

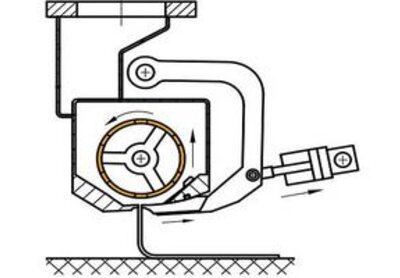

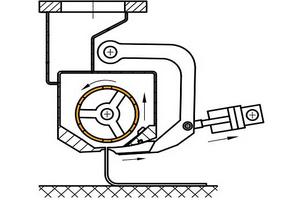

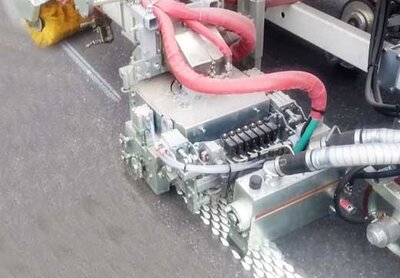

The rotating hollow cylinder for the exact determination of the marking patterns is located inside of the extruder housing. Thus, no heat problems resulting from too low ambient temperatures and wind.

Agglomerate and plain line markings with exact line beginnings and endings as well as no material splashes between the “dots” and in line-gaps due to heated extruder shutters. Furthermore by heating until outlet onto the road surface, the temperature of the material is kept constant (no problems with cooling down).

Ensurance of path-dependency (AMAKOS®) with MultiDotLine®- and MultiDotLine® Plus systems.

Application of double lines and line combinations in one single marking operation.

High marking speeds.