Cold plastic plain and profiled lines – so that you feel the variation

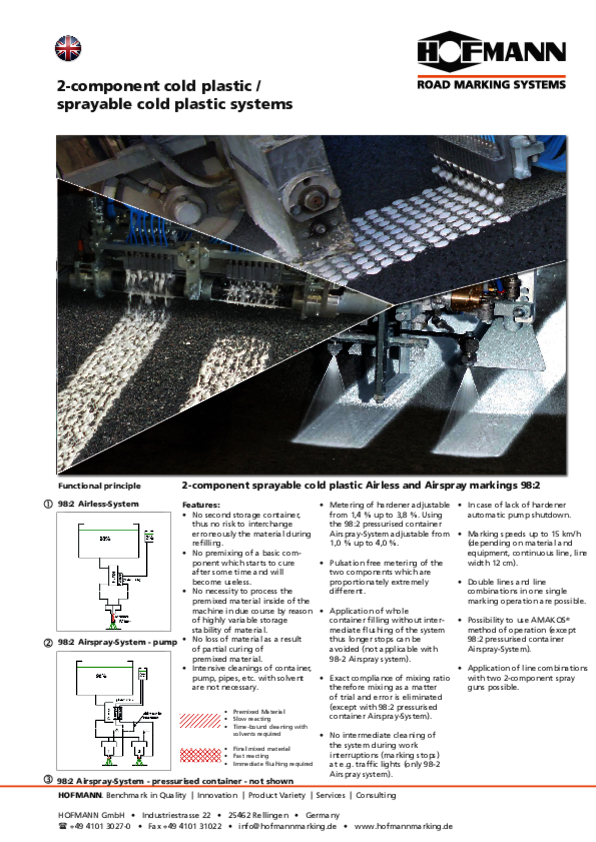

Plain and profiled markings with 2-component cold plastic, mixing ratio 98:2 applied with:

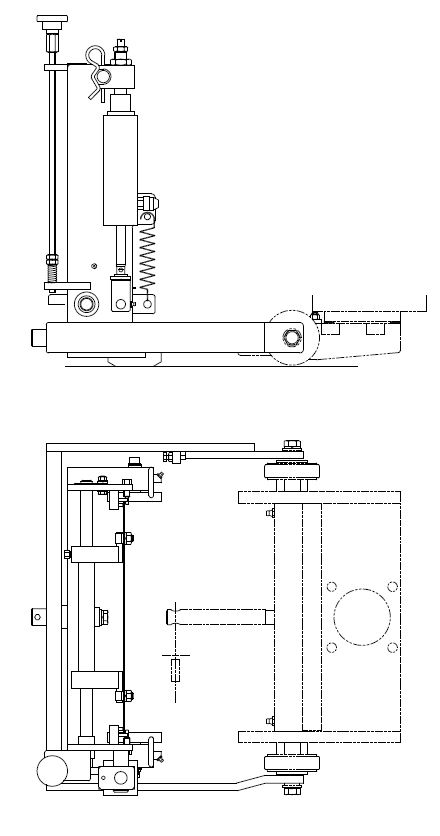

- Bellow pump system (path-dependent)

- Universal-Extruder-System (path-dependent)

- Pressurised container system (non-path-dependent)

- Screed box system (non-path-dependen

Features

Available application techniques

2 component cold-plastics

2 component cold-plastics

Following applications are possible:

- Profiles on base line, possible as continuous line and line-gap combinations.

- Profiles without base line.

Application of whole container filling without intermediate flushing of the corresponding systems (bellow pump, extruder and pressurised container) thus longer stops can be avoided.

Exact compliance of mixing ratio, therefore mixing as a matter of trial and error is eliminated.

Marking speeds up to 8 km/h*) can be achieved (bellow pump, extruder and pressurised container).

Using the screed box system up to 2 km/h*). Profiled markings: speeds up to 2 km/h*) can be achieved.

Suitable for the application of highly abrasive mediums and solid matters with a size of up to Ø 2,5 mm (bellow pump and pressurised container) as well as up to Ø 0,6 mm (extruder and screed box).

Acoustic warning signal in case of lack of hardener. Fulfillment of regulations is ensured with regard to automatic compliance of adjusted line thickness/material quantity.

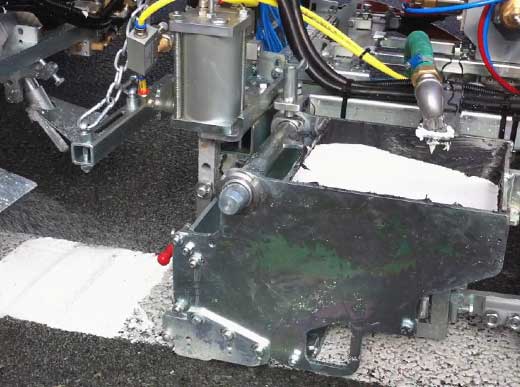

Quick exchange system for screed boxes. 90° cross profiled markings up to 16 mm height (depending on material) with and without chamfered edges.

Possibility to use AMAKOS® method of operation.

*) dependent on material and equipment, continuous line, line width 12 cm

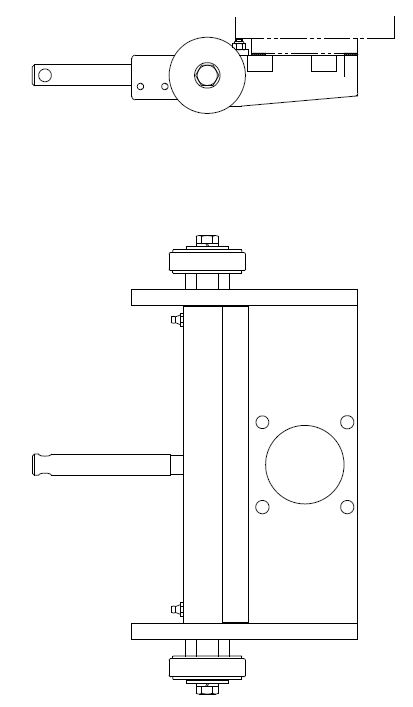

Function Principle

Available application techniques

2 component cold-plastics

2 component cold-plastics

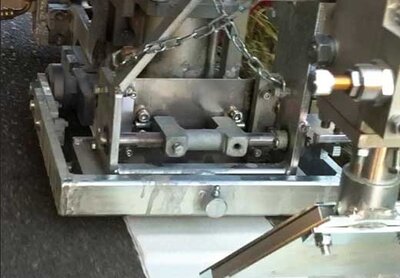

Shutter / Flap system

2-component cold plastic - Closed mixing and application unit for plain markings

2-component cold plastic - Closed mixing and application unit for plain markings

2-component cold plastic - Closed mixing and application unit for plain markings

2-component cold plastic - Closed mixing and application unit for plain markings

2-component cold plastic - plain markings via closed mixing and application unit

2-component cold plastic - profiled markings via closed mixing and application unit