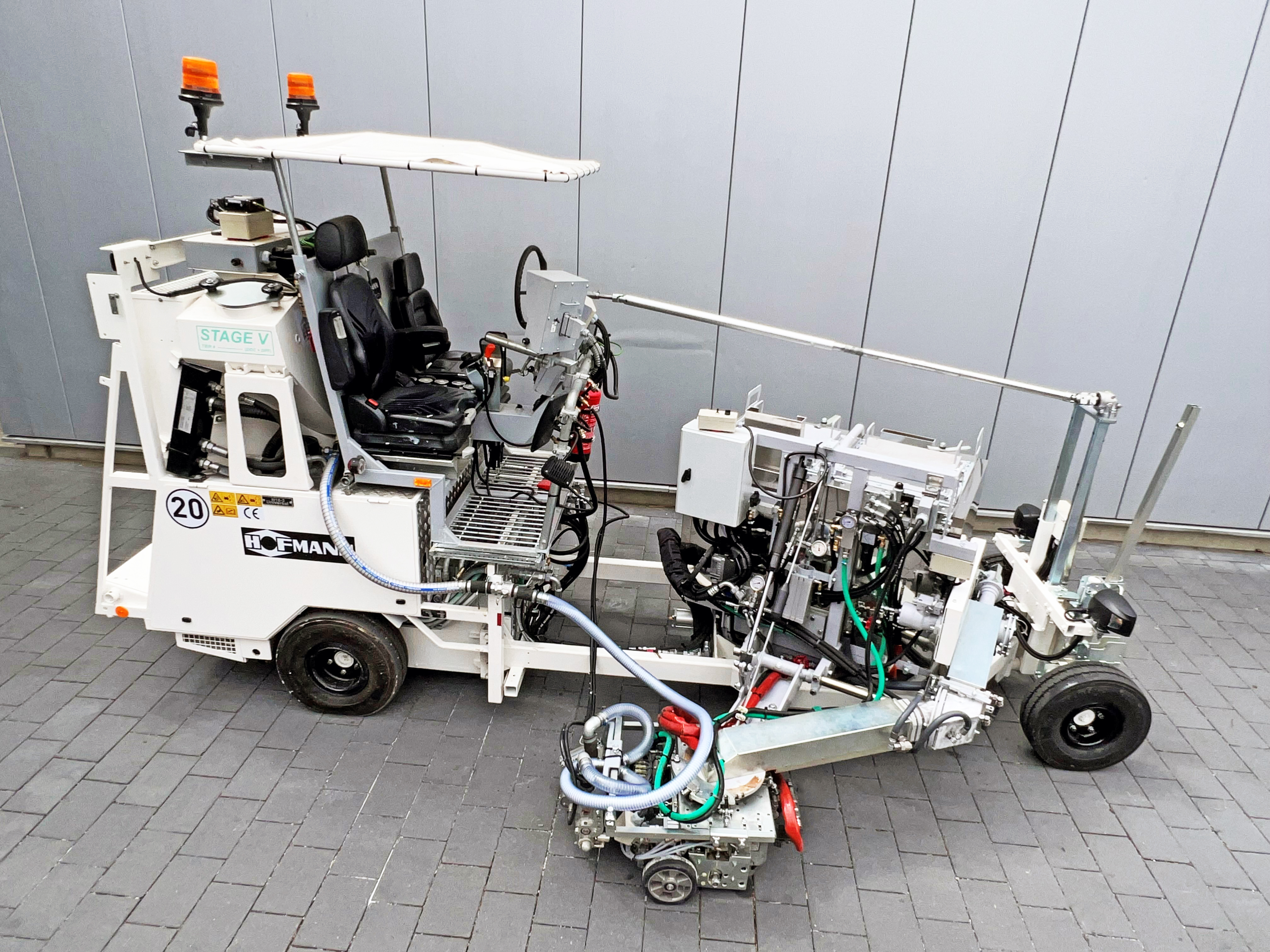

H18-2

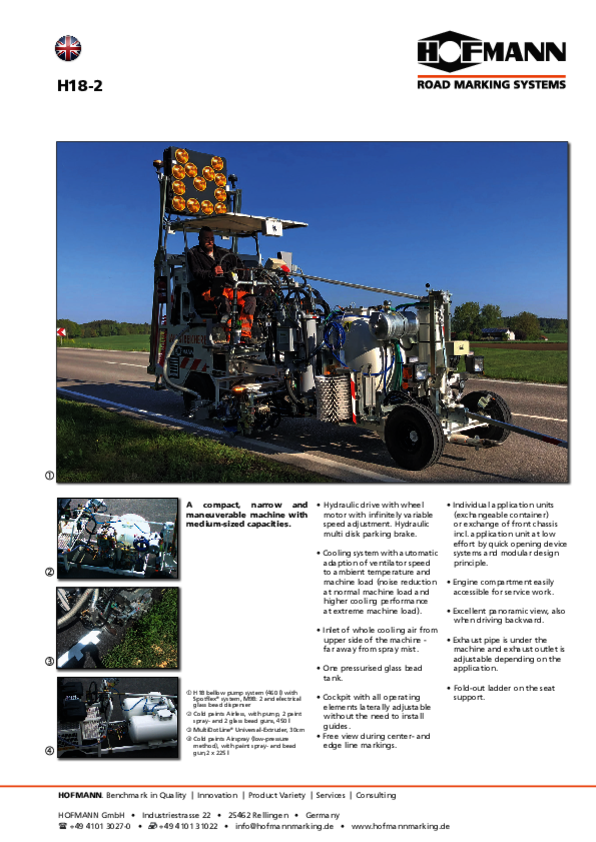

A compact, narrow and maneuverable machine with medium-sized capacities

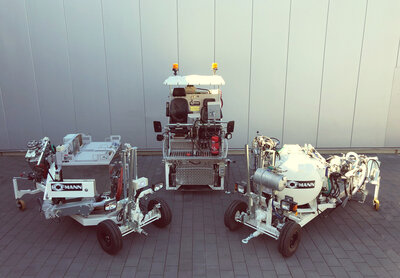

Figure: example machine out of H18 product line

Available Application techniques

Description

Hydraulic drive with wheel motor with infinitely variable speed adjustment

Hydraulic multi-disk parking brake

Cooling system with automatic adaption of ventilator speed to ambient temperature and machine load (noise reduction at normal machine load and higher cooling performance at extreme machine load)

Inlet of whole cooling air from upper side of the machine - far away from spray mist

Exhaust pipe is under the machine and outlet is adjustable depending on the application

One pressurised glass bead container

Cockpit with all operating elements adjustable without the need to install guides

High visibility during center- and edge line markings

Fold-out ladder on the seat support

Individual application units (exchangeable container) or exchange of front chassis incl. application unit at low effort by quick opening device systems and modular design principle

Engine compartment easily accessible for service work

Excellent panoramic view, also when driving backwards

Line widths:

10 up to 100 cm (dependent on equipment)

Specifications

4 cylinder 2400 cm³

Kubota Turbo Diesel Motor

water-cooled

Version I: **

Non label (comparable to EU Stage IIIA resp. (US) EPA Tier 4 Interim)

44,0 kW at 2700 rpm

Version II: **

low-emission EU Stage V resp. (US) EPA Tier 4

with diesel oxidation catalyst (DOC) and

Diesel Particulate Filter (DPF)

48,6 kW at 2700 rpm

** further exhaus stages upon request

Air output, alternatively:

1300 - 2200 l/min at 7,5 bar; compressed-air cooler

Pressurised glass bead container:

170 l (max. 0,8 bar)

Dimensions (L x W x H mm):

4260 up 5600 x 1260 x 2300

(dependent on equipment)

Techniques / Container volumes: (dependent on equipment)

| Cold paints | up to 540 l |

| 2-component cold-plastics | up to 540 l |

| Sprayable 2-component spray-plastics | up to 540 l |

| Thermoplastics | up to 420 l |

| Sprayable Thermoplastics | up to 320 l |

Photos

Videos

Brochures

Equipments

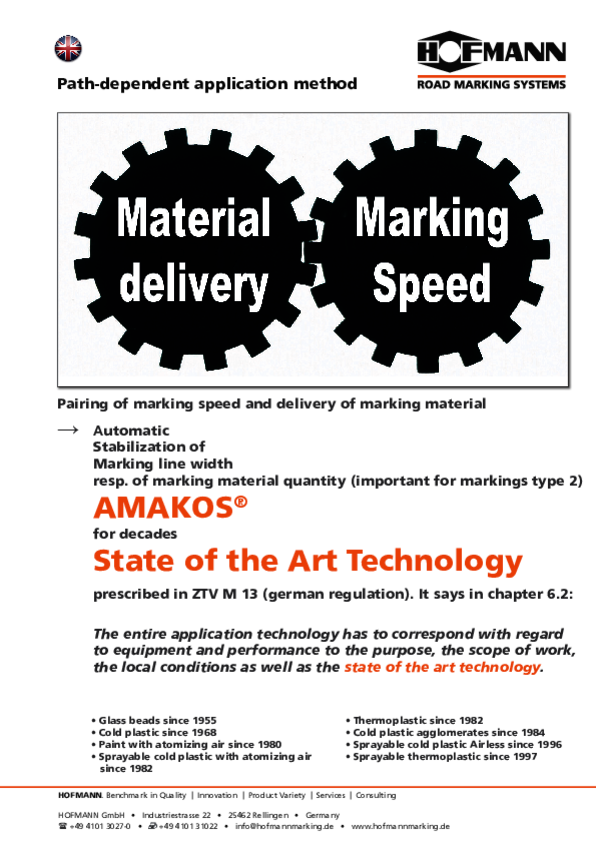

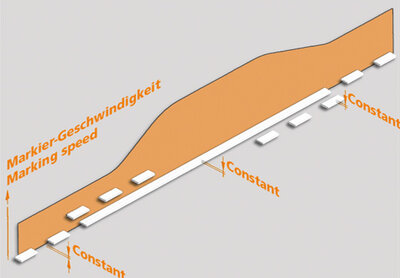

Metering technology / AMAKOS®

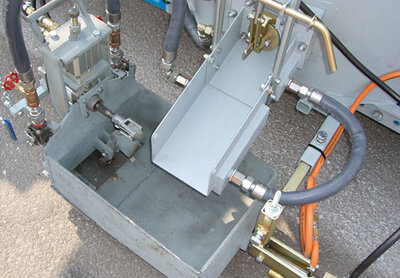

CONEX® - Metering pump system

MALCON4/4E

ELC4

Accessories

Preheaters

Specialties

Simply Palletisable System

Outlet Tube

Protective Covers

Dryer Unit

Rear view camera

Premarking device

Additional Rear Platform

Marking Patterns

Available Application techniques

Remarks

All information is given without the use of glass bead guns, since in this case the required air flow rate has to be calculated.

The line widths and gaps for double lines depend on the equipment.

Combined double lines, especially for hand-guided machines, are often dependent on the equipment and require, among other things, the addition of higher-grade line-gap electronics.

Special solutions on request.