H17

A very narrow and extremely manoeuvrable machine with medium capacities

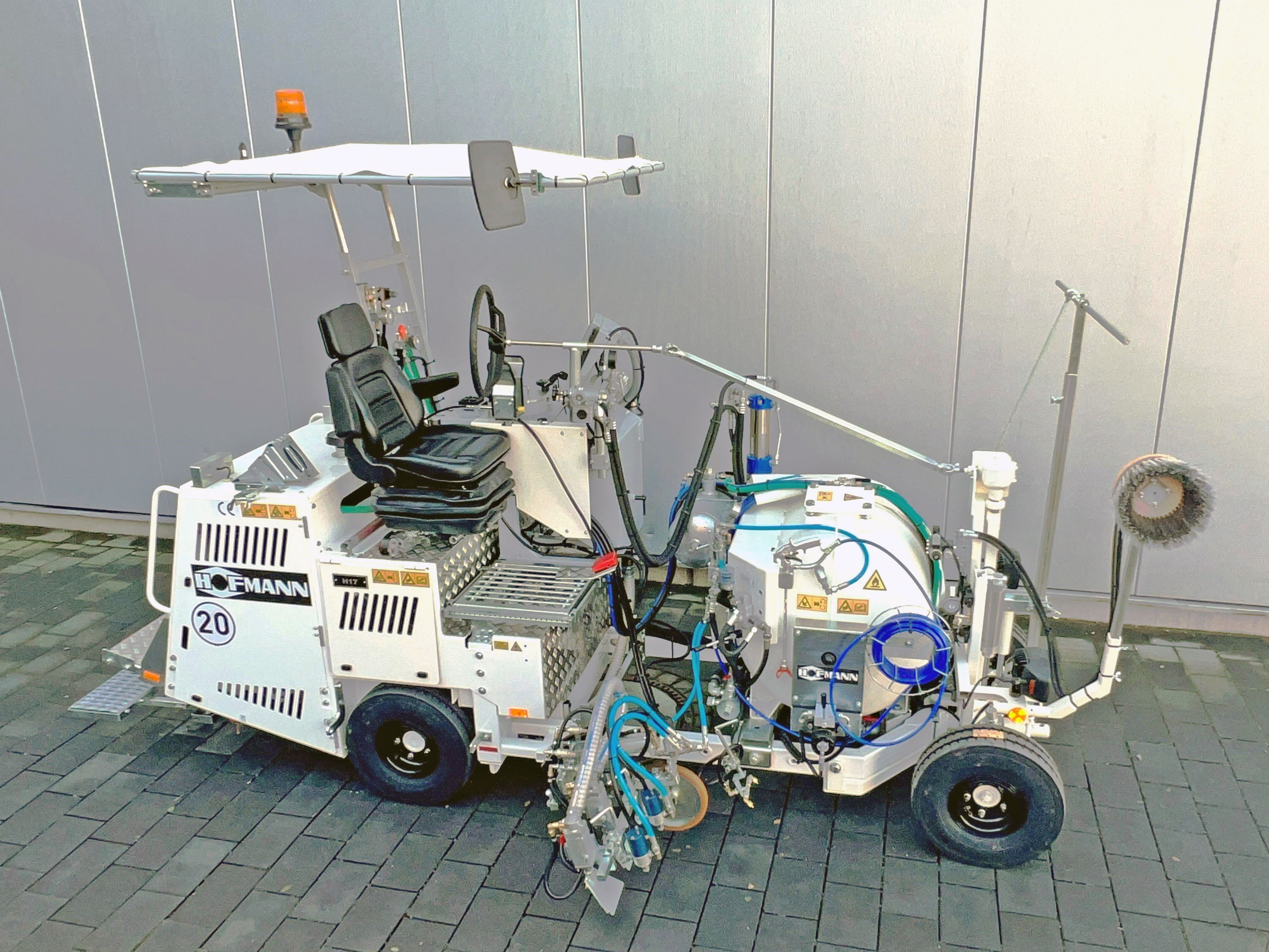

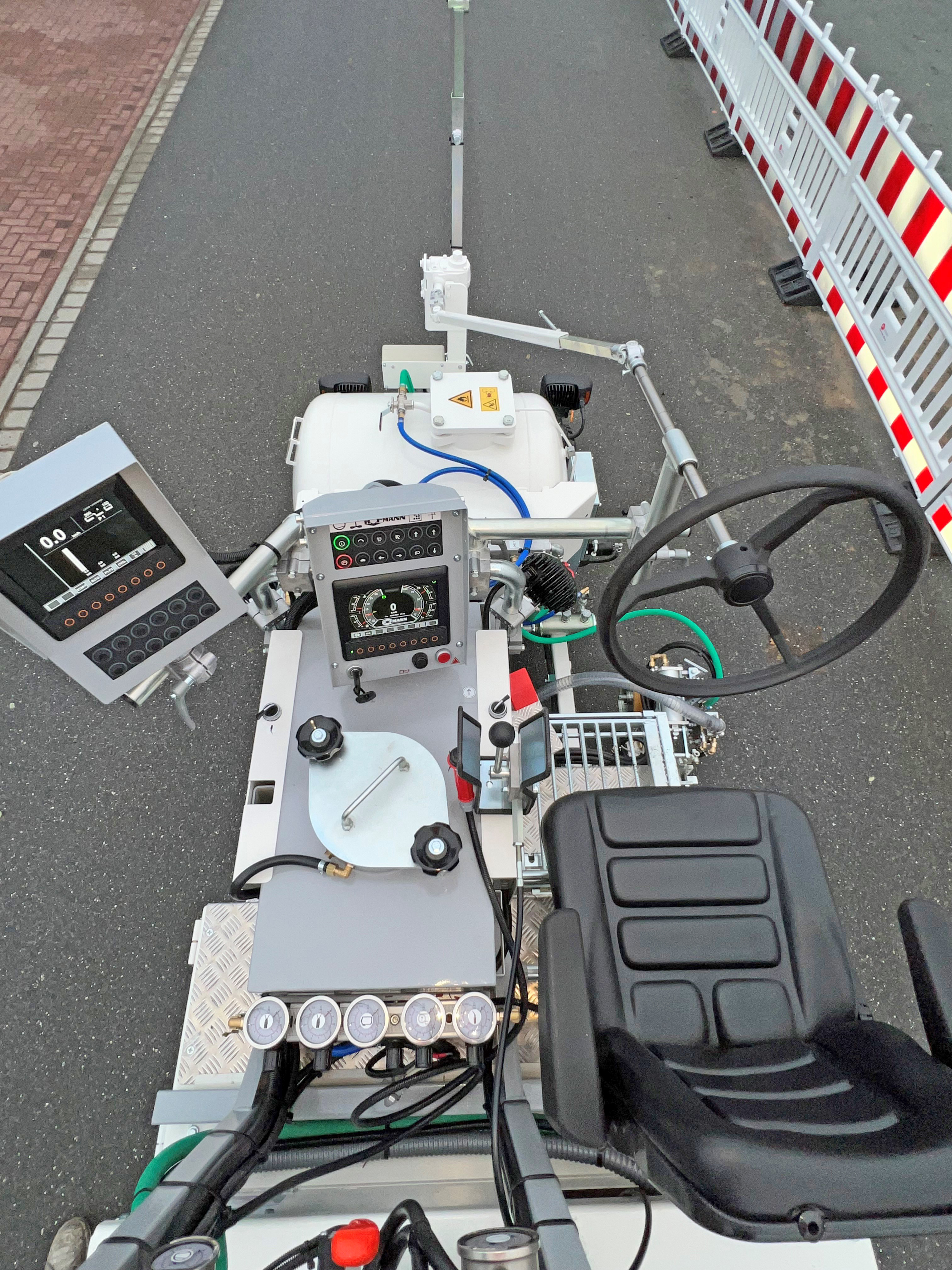

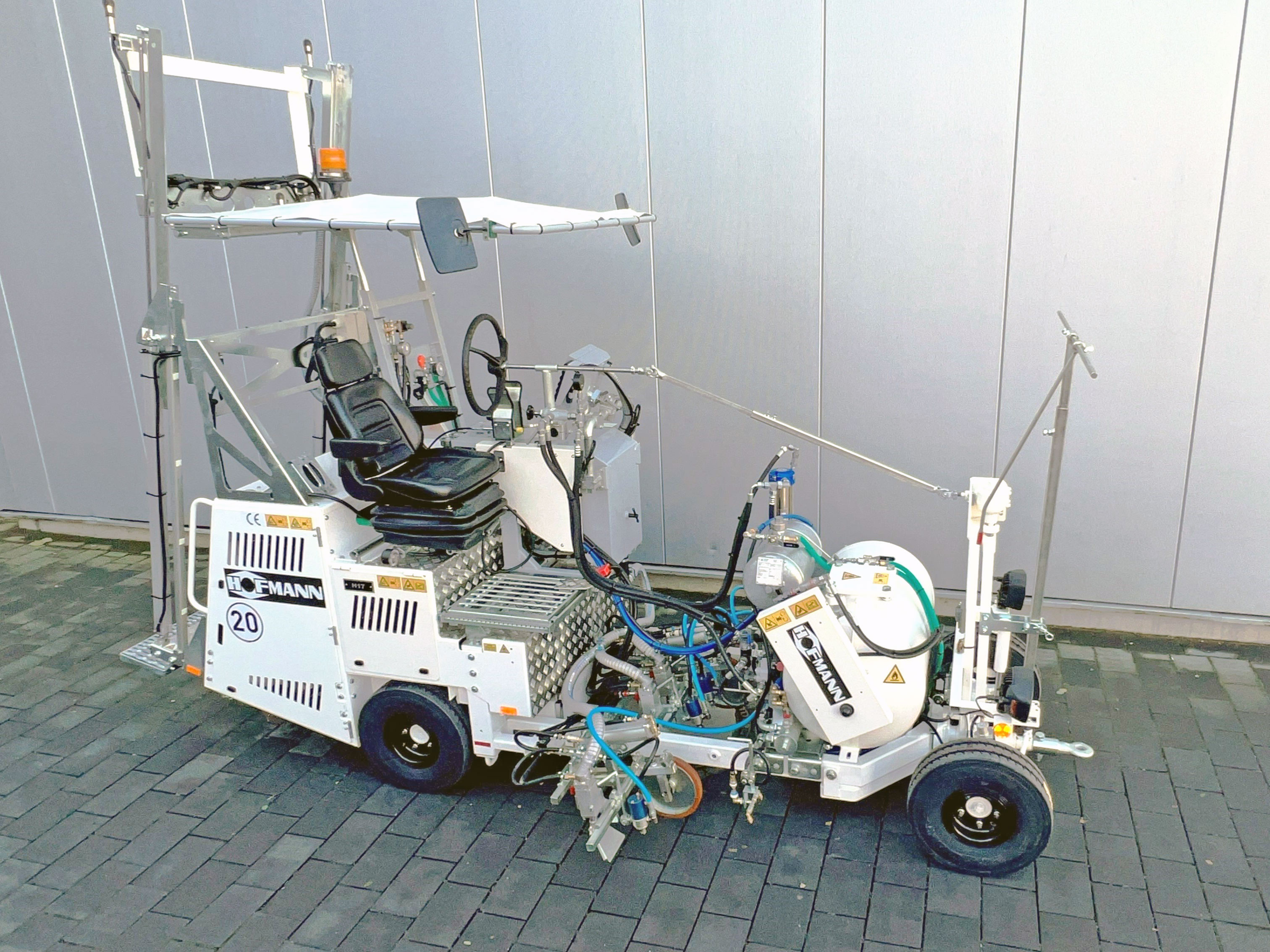

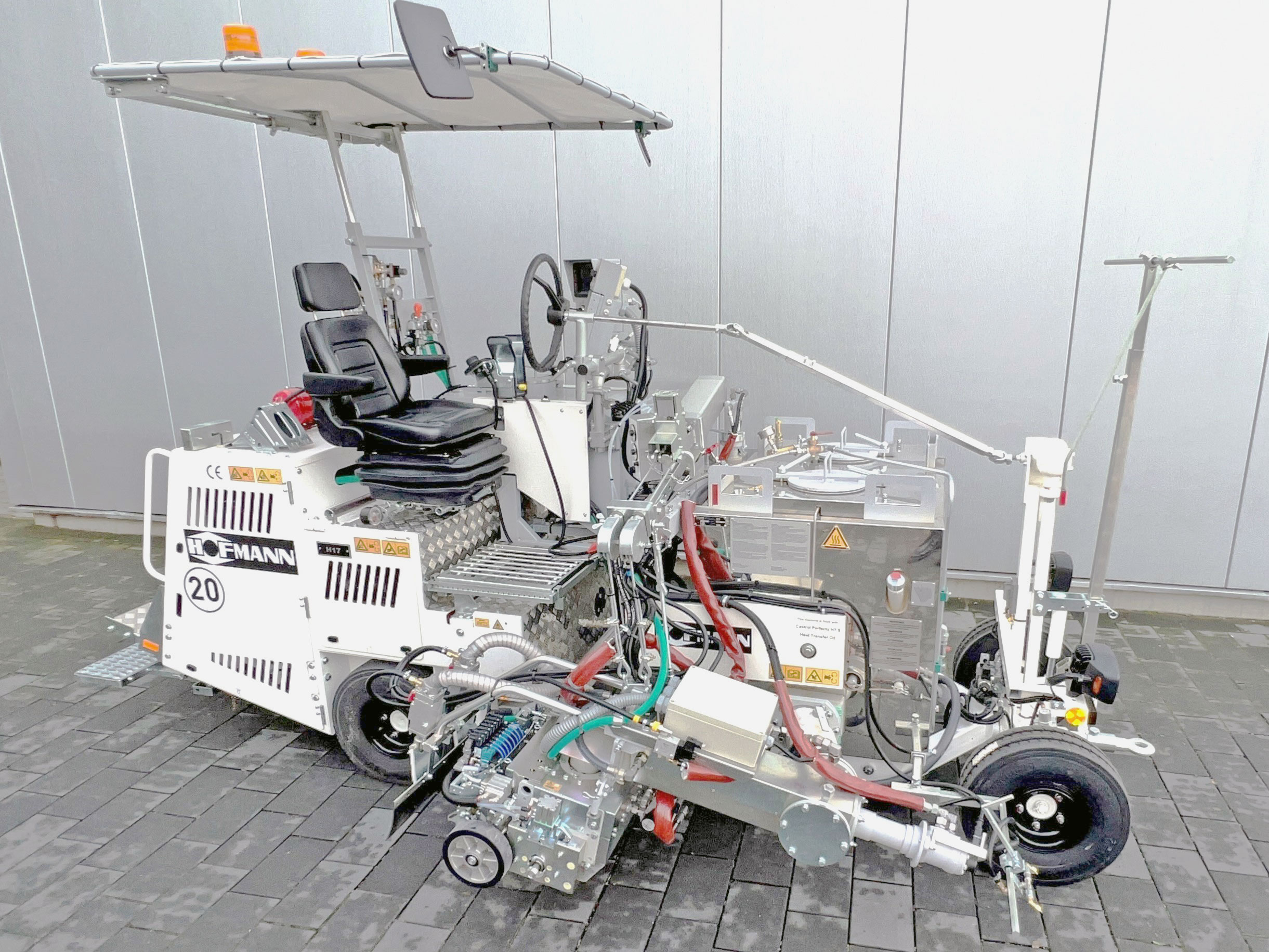

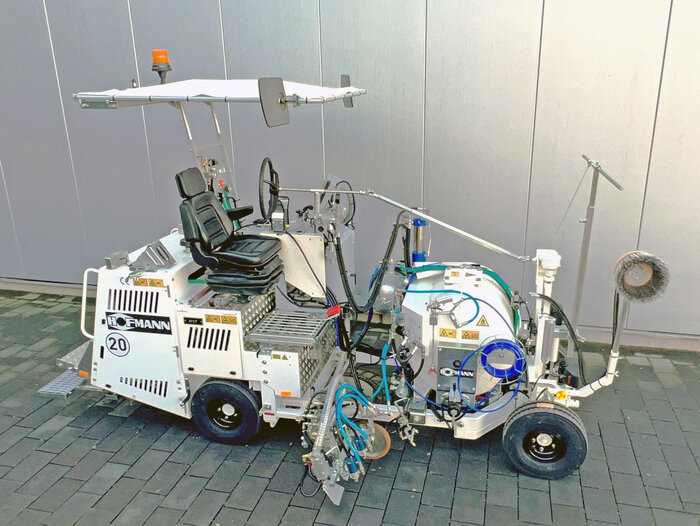

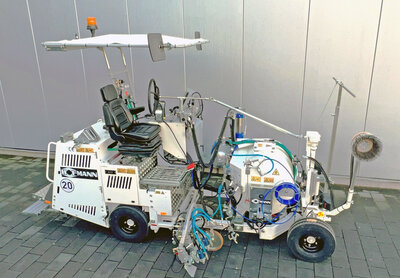

Figure: example machine out of H17 product line

Available Application techniques

Description

Hydraulic drive with wheel motor for infinitely variable speed regulation

Hydraulic multiple disk parking brake

Cockpit with all operating elements can be moved to both sides. Operating elements can be adapted to the other side and the seat element can be switched to the other side.

Engine compartment easily accessible for service work

Excellent panoramic view, also when driving backwards.

Line widths:

10 up to 60 cm (dependent on equipment)

Specifications

4-cylinder 1500 cm³,

Kubota Turbo diesel motor,

water-cooled

Version I:

Non-Label (comparable to EU Stage IIIA resp. (US) EPA Tier 3)

Version II:

Low-emission EU Stage V resp. (US) EPA Tier 4 with diesel oxidation catalyst (DOC) and Diesel Particulate Filter (DPF)

33,0 kW at 3000 U/min

Air output:

up to 800 - 1200 l/min at 7,5 bar; compressed air cooler

Pressurised bead container:

100 l (max. 0,8 bar)

Dimensions (L x W x H mm):

3580 x 1210 x 2270

(dependent on equipment, only basic machine and without options)

Weight, equipped:

approx. 1700 - 2300 kg

approx. 3747 - 5070 lbs

Total admissible weight:

approx. 3300 kg / 7275 lbs

Techniques / Container volumes: (dependent on equipment)

| Cold paints | up to 370 l |

| 2-component cold plastics | up to 370 l |

| Sprayable 2-component cold plastics | up to 370 l |

| Thermoplastics | up to 420 l |

| Sprayable Thermoplastics | up to 250 l |

Photos

Videos

Equipments

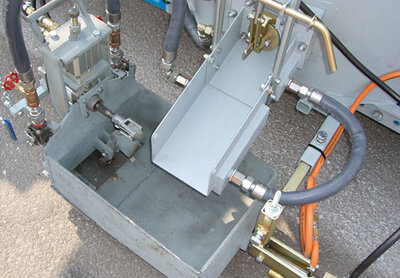

Metering technology / AMAKOS®

CONEX® - Metering pump system

MALCON4/4E

ELC4

ELC1plus

Accessories

Preheaters

Specialties

Outlet Tube

Protective Covers

Rear view camera

Premarking device

Additional Rear Platform

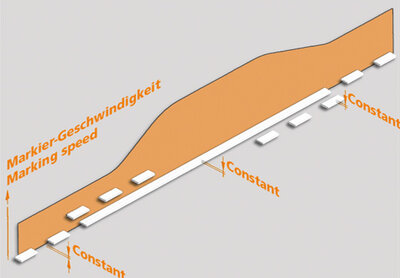

Marking Patterns

Available Application techniques

Remarks

All information is given without the use of glass bead guns, since in this case the required air flow rate has to be calculated.

The line widths and gaps for double lines depend on the equipment.

Combined double lines, especially for hand-guided machines, are often dependent on the equipment and require, among other things, the addition of higher-grade line-gap electronics.

Special solutions on request.