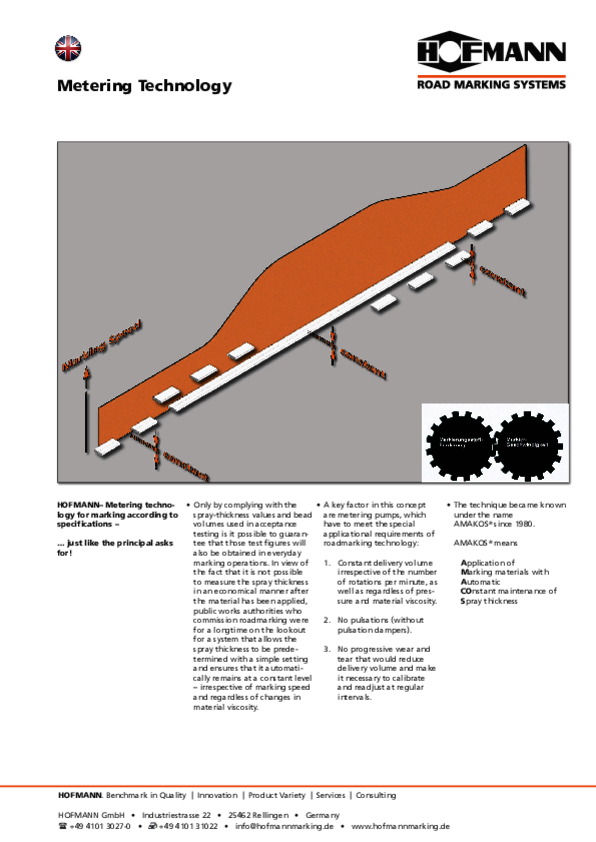

CONEX® - Metering pump system

Metering pump for CONstant EXacte metering of different materials

Use of plunger- or bellow pumps according to application technique

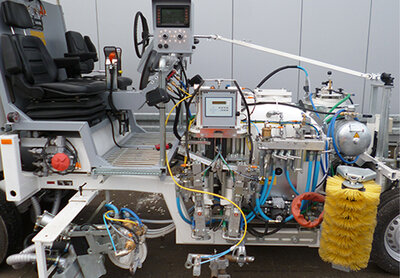

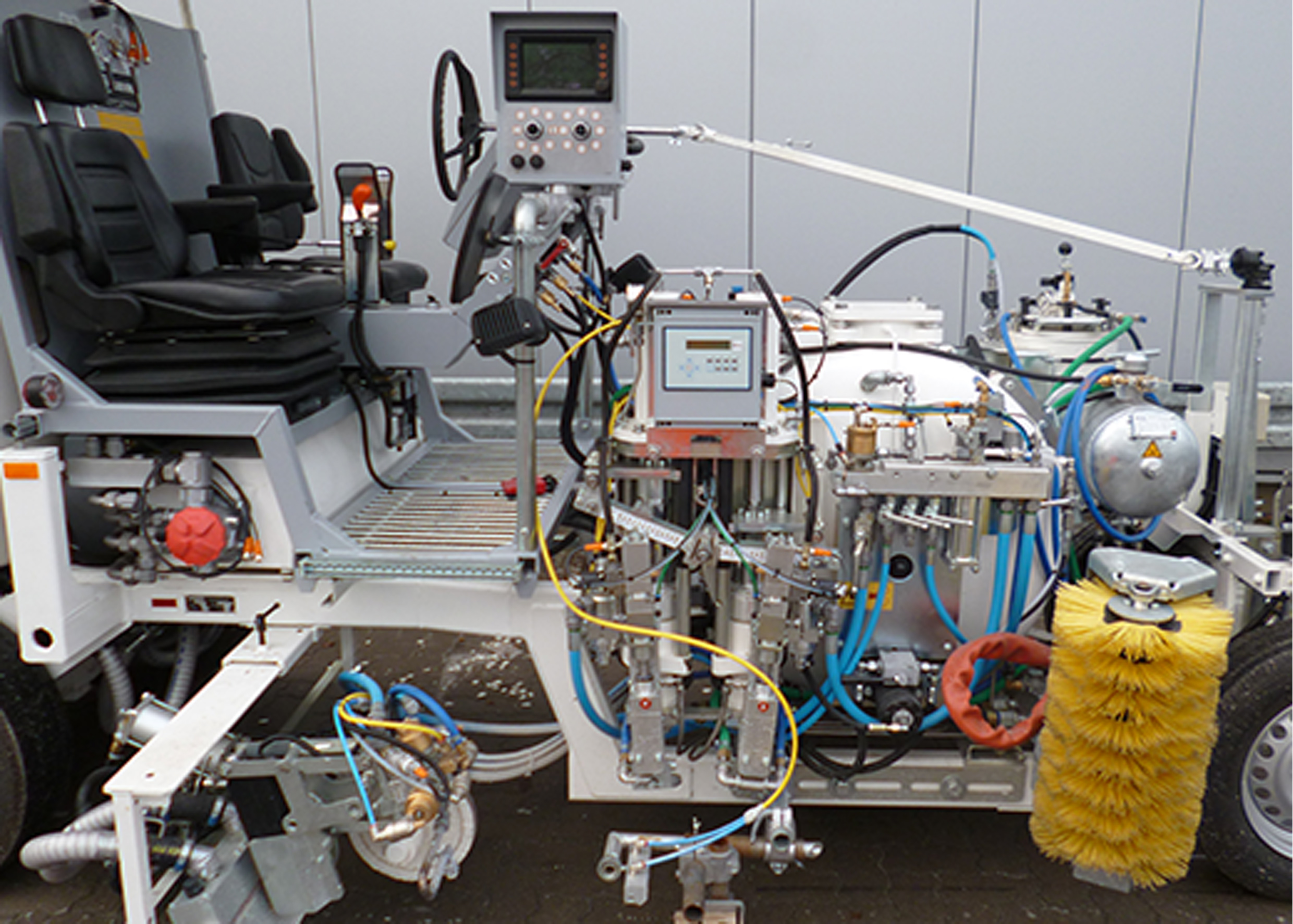

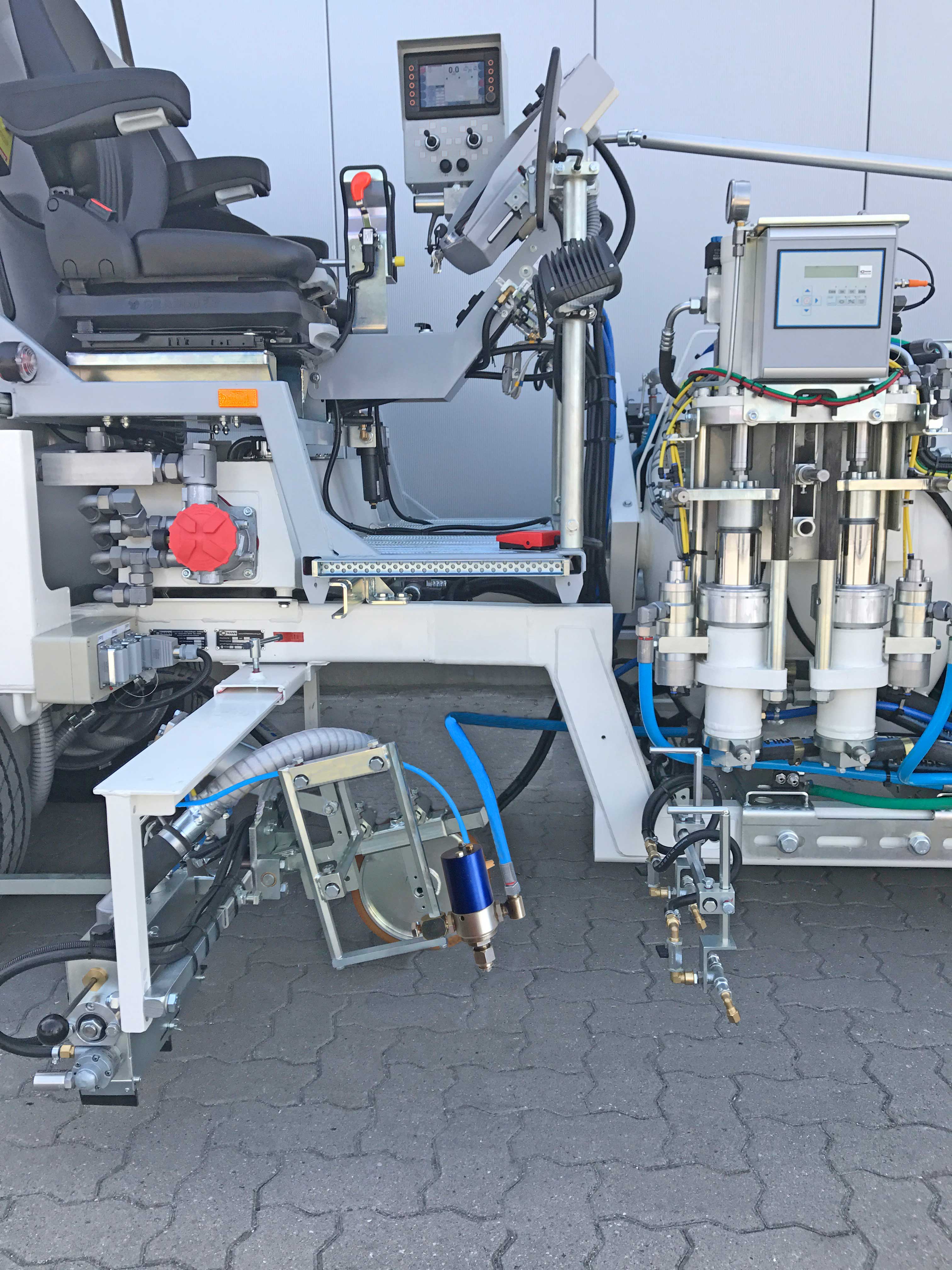

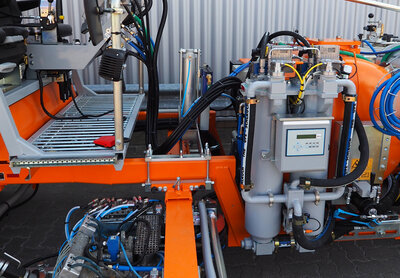

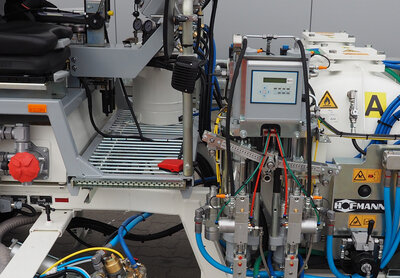

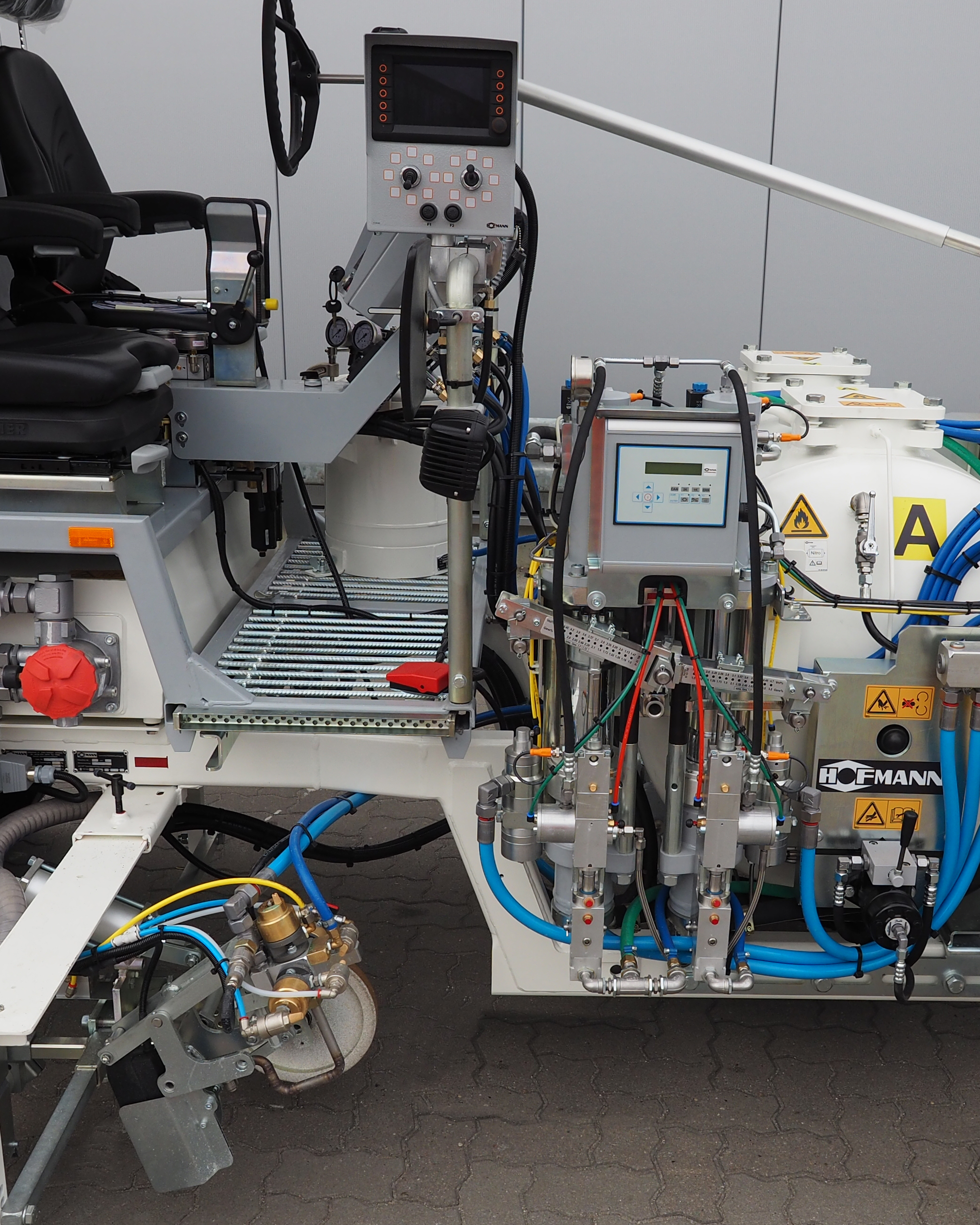

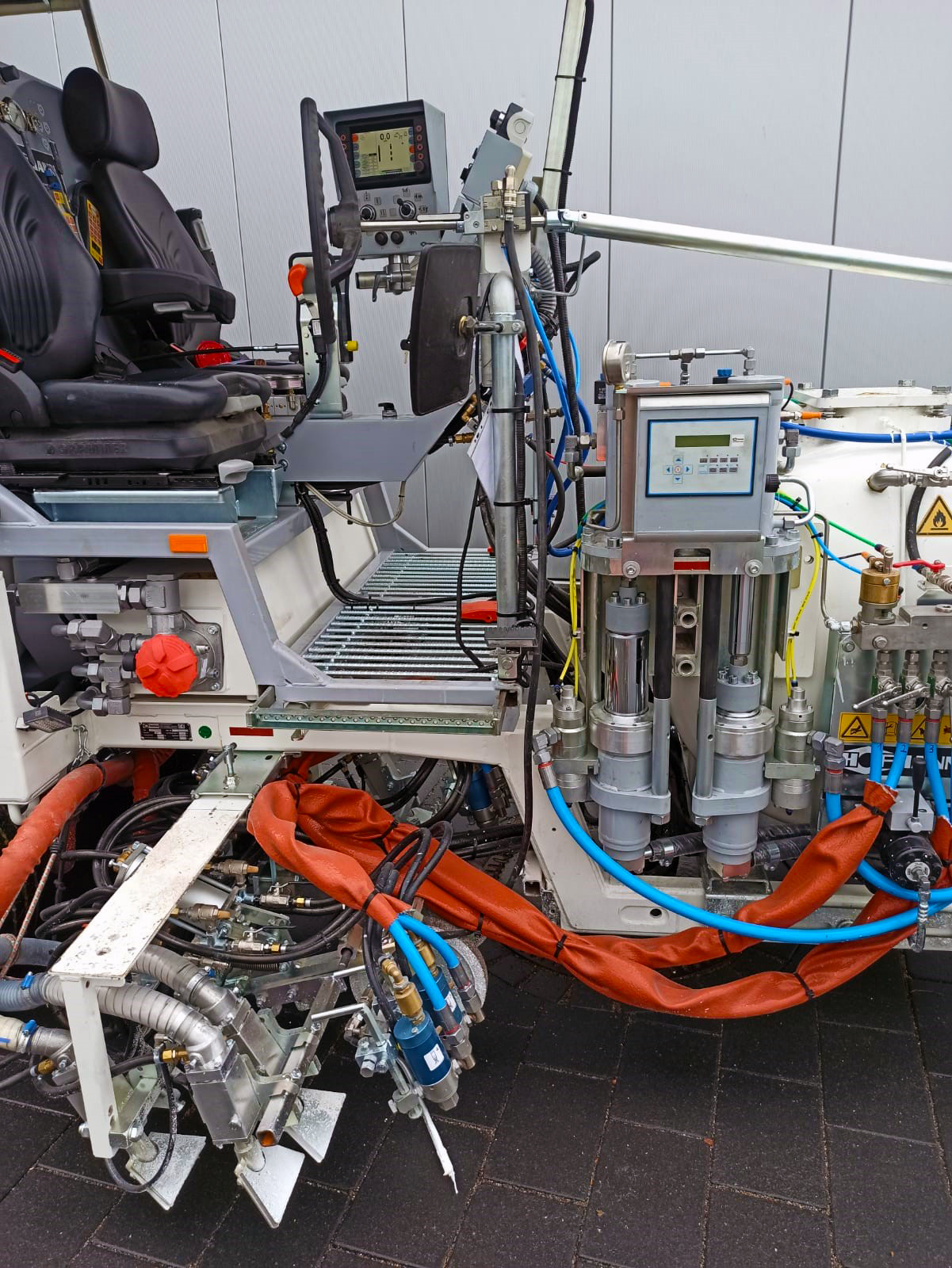

Figure: Example of a pump out of CONEX® product line

Available Application techniques

Description

Can be used for nearly all cold and hot applied marking materials with and without mixed-in glass beads / anti skid materials (abrasive materials)

Plunger pump:

No concealed working pistons inside the discharge cylinder, just visually inspectable seals against the outside. Optimum strain effect on the sealing.The stress on the sealing is a stretch load, in contrast to conventional piston pumps with pulling and strongly stressed pressing sealing process. Precondition for the application of abrasive materials.

Bellow pump:

No concealed working pistons inside the discharge cylinder since it is a seal-free system.

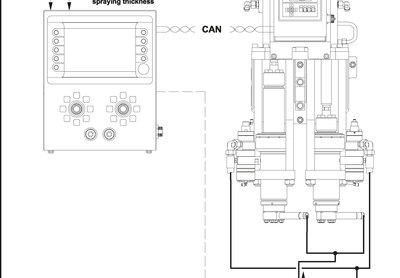

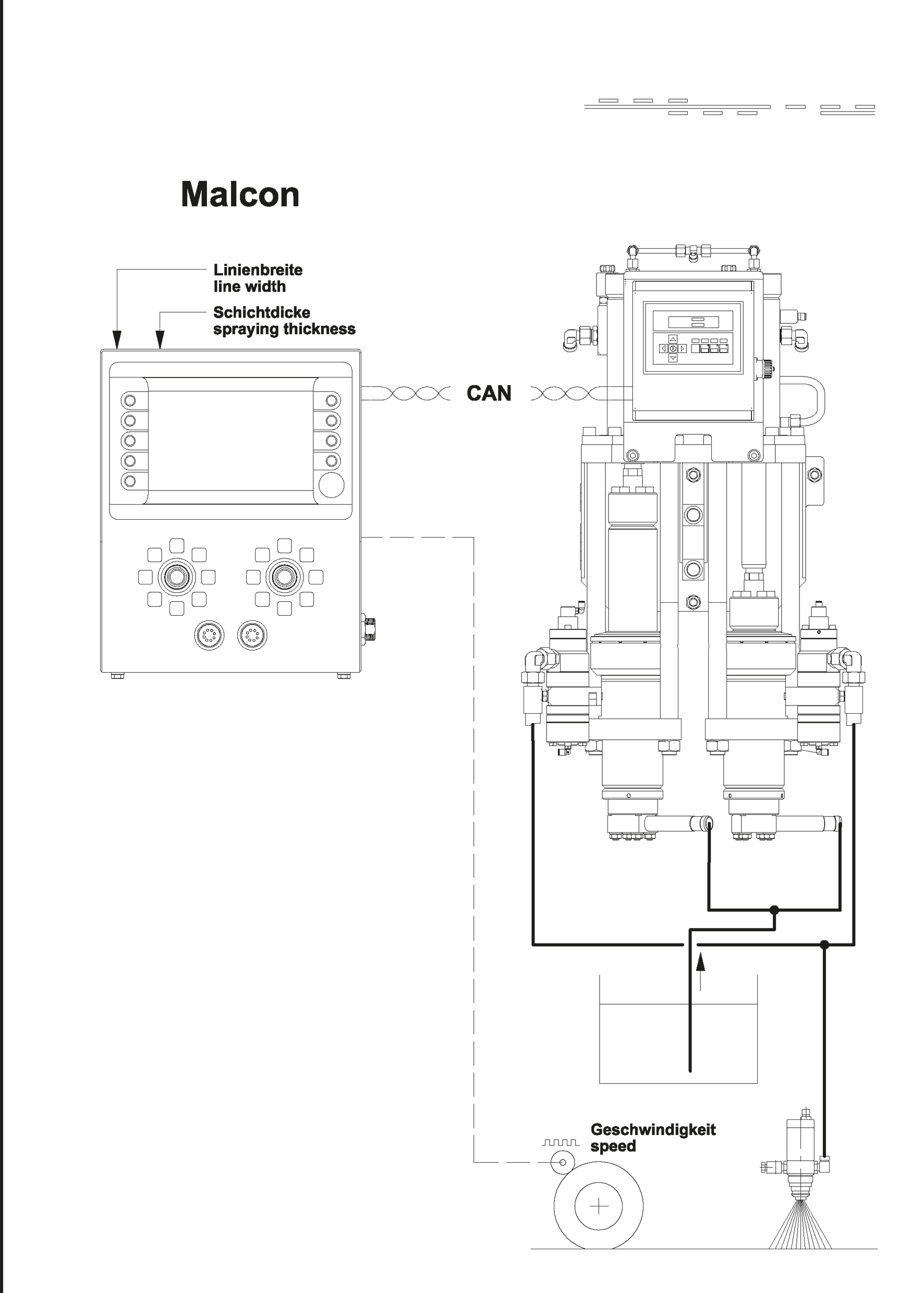

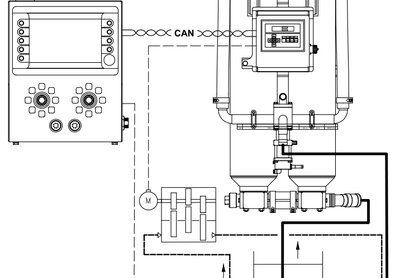

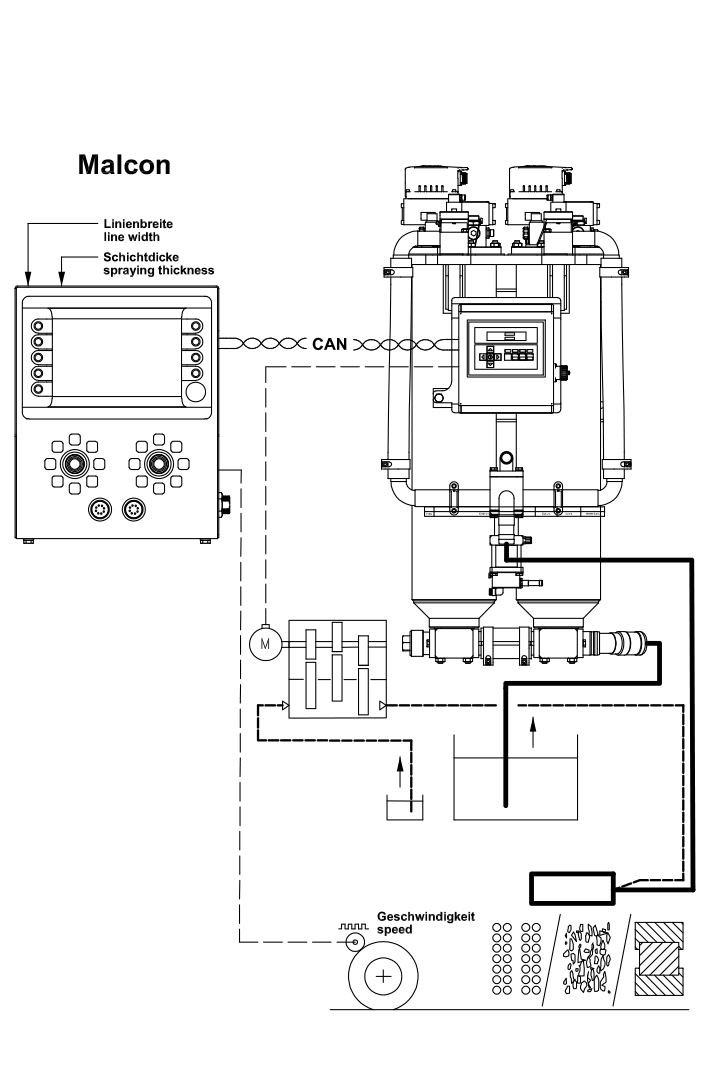

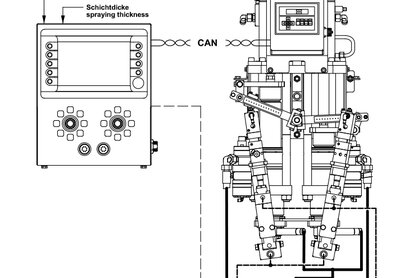

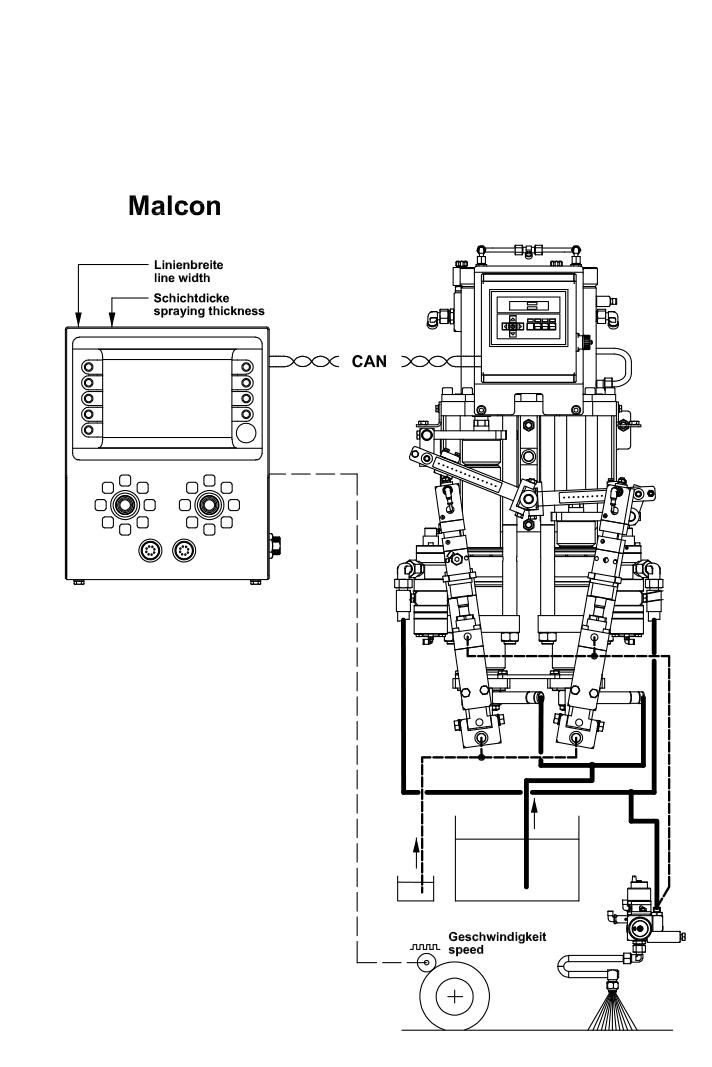

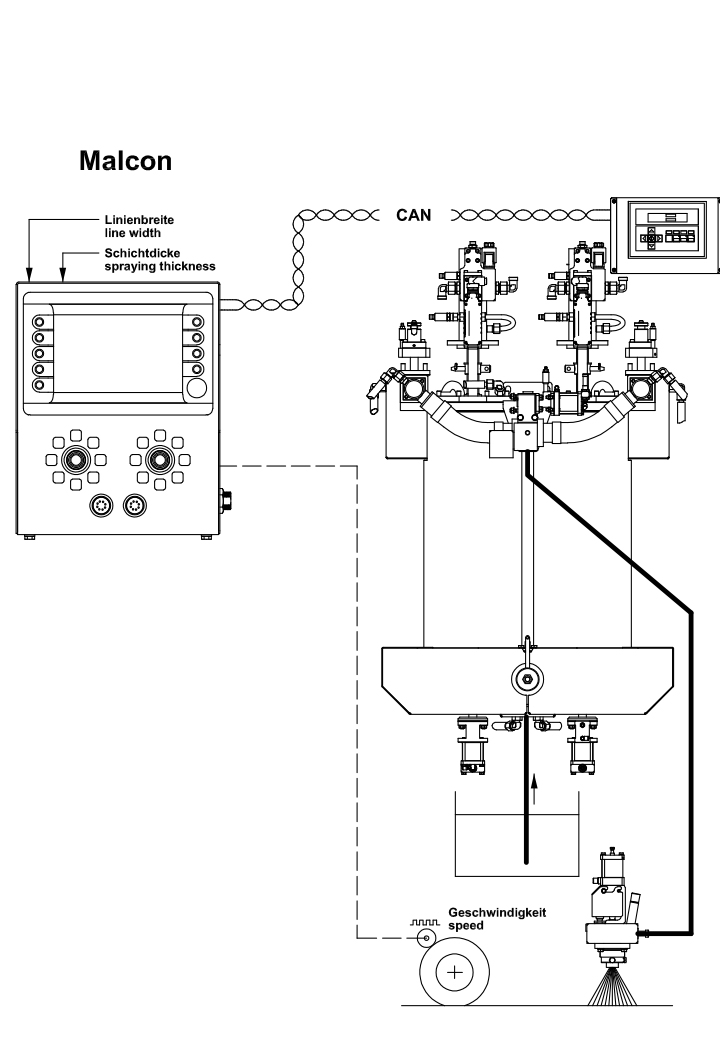

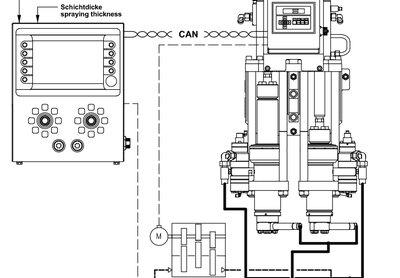

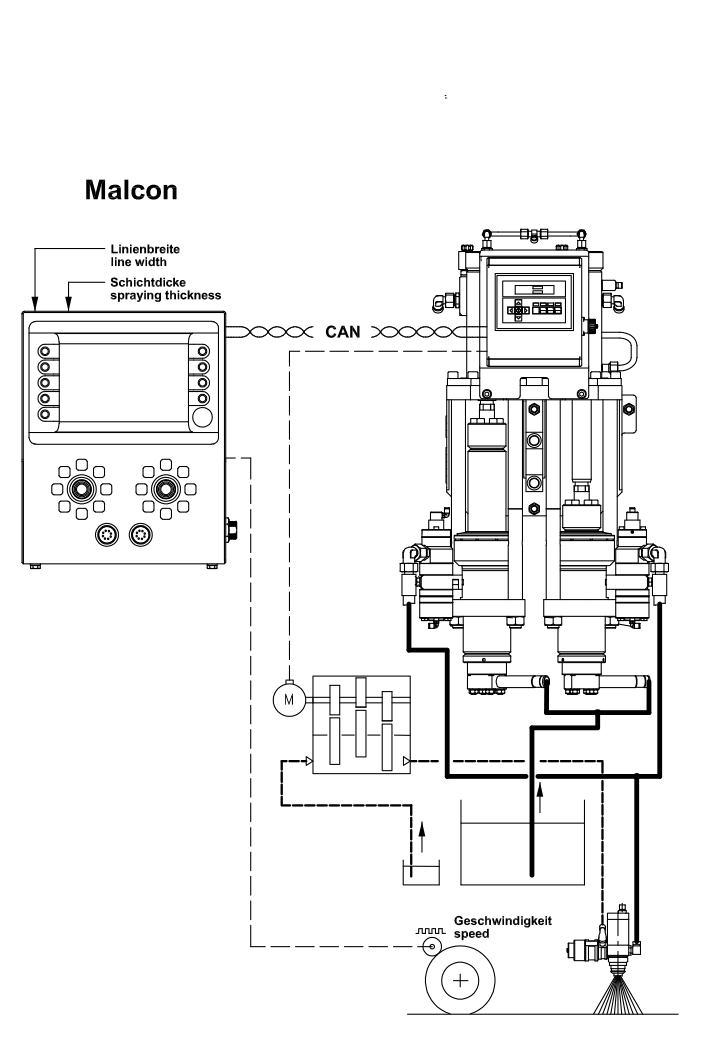

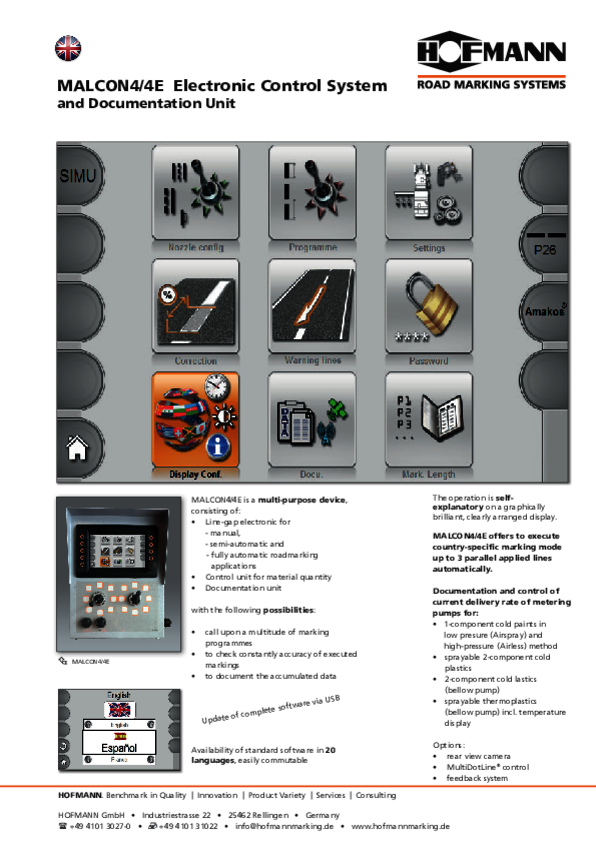

MALCON4: Control unit that allows to enter marking line values for width and thickness

The necessary material quantity in accordance with the speed is transmitted via CAN bus to the pump which supplies the controlled quantity of material

The line thickness resulting from the feedback is logged with GPS coordinates in compliance to ZTV-M (German Additional Technical Contractual Conditions and Directives for Marking on Streets)

By entering other specification data you can create logs which are often required by contractors

No negative pulsation and no flow losses which could be detrimental to the road marking quality

Specifications

Metering pumps for 1 component cold paint applications

Delivery rates:

12 l/min, 18 l/min or 24 l/min

Metering pumps for 2 component cold plastic applications

Delivery rate:

approx. 35 l/min

Metering pumps for 2 component sprayable cold plastic applications

Delivery rate:

12 l/min, 18 l/min or 24 l/min

Metering pumps for sprayable thermoplastic applications

Delivery rate:

approx. 40 l/min